Structure:

DIN 4112 non-permanent structures; structural design, construction and operation

DIN 13814 fairground and amusement park machinery and structures

Eurocode 3: DIN EN 1993–1–1; 2005–07

Electrical system and installation:

VDE 0100

Electro-magnetic compatibility

EN 55022: 1988 + A1: 2000 + A2: 2003, class A

FCC 47 CFR Ch.1 Part 15 2007–09–20

The electrical system is designed for a main power supply of 120V / 60H / 150 Amps. This main power has to be locally provided.

Before setting up operation an initial electrical test according VDE 0100 part 610 and if requested also related to local requirements must take place including all prescribed test-charts.

Installation guide:

Electric Fountain is packed in three 40-foot sea containers. Without knowing all specifications, regulations of, and site conditions in situ of a place of exhibition it does not make sense to give a define information regarding the way of delivery of all equipment serving the site.

In general there are two main options:

(i) all sea containers are shipped to the site and have to be placed and to stay there during all installation & de-installation periods, which also means a crane for unloading / loading the containers from a truck has to provided

(ii) all sea containers are shipped to a specialized store, where they can be unpacked and where immediately after arrival all components can be checked regarding any transport damage, especially broken neon tubes. That way the site will be served by multi-deliveries and pick up of crates as needed and on time

Option (ii) is preferable.

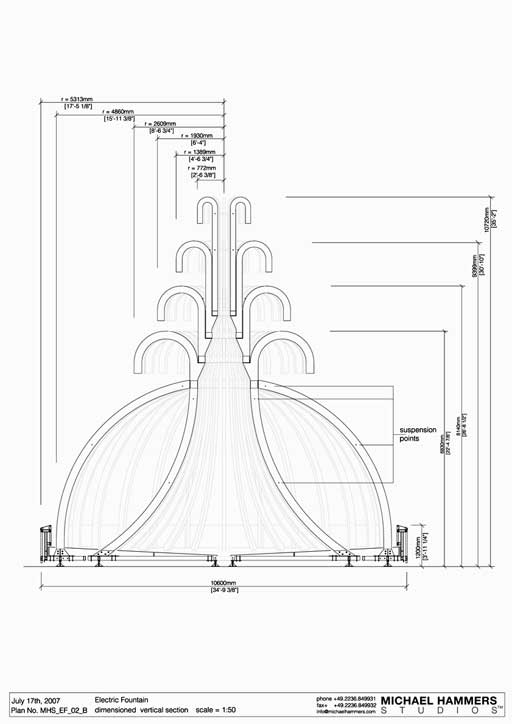

Dimensions:

diameter: 10,60m => 34' 9 3/8"

height: 10,72m => 35' 2"

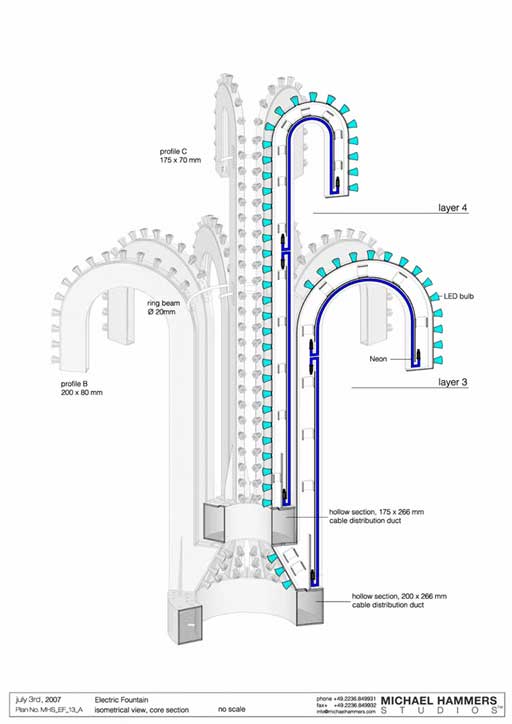

number of LED: 3390, 12V controlled low voltage system

length of neon: 527m, 5000V high Voltage system

weight: 25800 kg => 56879 lbs

transmitted to the ground by 47 adjustable feet

calculated max load / foot incl. wind-, snow-load, safety addition

18KN => 1835kg => 4045 lbs

Power supply:

operating consumption: max 18 KW/h

3 phases + neutral + ground

120V 60H

max. 150 Amps

supply-line: cable 5 x 502mm (AWG 1)

phase to phase 240V

phase to neutral 120V

phase to ground 120V

phase 1 – 45Amps

phase 2 – 45Amps

phase 3 – 42Amps

max. 150 Amps

Site conditions:

required area for Electric Fountain at final position

15m x 15m (49' 2 1/2" x 49' 2 1/2")

required area for storing and crane min

15m x 25m (49' 2 1/2" x 82' 1/4")

required area for assembly (Electric Fountain area included)

15m x 20,5m (49' 2 1/2" x 67' 3 1/8")

Packing and transport:

three 40-feet sea containers

dimensions: LBH 12,19m x 2,44m x 2,59m (40' x 8' x 8' 6")

two transport racks (10 inner beams each)

LBH 5,70 x 1,10m x 2,30m (18' 8" x 3' 7" x 7' 6") approx. 3,5t (7700 lbs)

four transport racks (6 outer beams each)

LBH 6,30m x 1,15m x 2,30m (20' 8" x 3' 9" x 7' 7") approx 2,5t (5500 lbs)

four transport racks (5 pieces level 1 each)

LBH 2,50m x 0,90m x 2,00m (8' 3" x 2' 11" x 6' 7) approx 700Kg (1550 lbs)

LBH 1,90m x 0,90m x 2,30m (6' 3" x 2' 11 x 7' 7") approx 500Kg (1100lbs)

four transport racks (3 pieces level 2 each)

LBH 2,70m x 0,90m x 1,60m (8' 10" x 2' 11" x 5' 3") approx 400Kg (900lbs)

1 transport rack (6 pieces level 4)

LBH 3,50m x 0,90m x 2,20m (11' 6" x 2' 11" x 7' 3") approx 750 Kg (1650 lbs)

1 pallet (rings of all levels )

LBH 2,20m x 2,20m x 0,80m (7' 3" x 7' 3" x 2' 8") approx 1500 Kg (3300 lbs)

other palettes with basis / substructure elements / shoring / basis cover / electrical components / tools / screws / small parts

Local services at site:

Electrician / electrical engineer

• to provide main power supply

• initial test and report if required

Carpenter

• custom made plywood underlay under each foot for levelling

• custom made plywood cover from basis to ground

• plywood for floor protection if necessary

Equipment, light

• two hand jacks

• two 12–15-feet ladders

• 110V / 60Hz or 220 / 50Hz power supply for hand tools

Equipment, heavy

• forklift 5t (11000lbs) to move heavy crates and to arrange pallets and elements (day 1–8 of installation / day 1–6 of dismantling)

• light crane to lift elements for assembly

(day 2–7 of installation / day 2–4 of dismantling)

max. load 2500kg (5500lbs) at min hook height 10m (33') and min operating range of 8m

and max load 300kg (660lbs) at min hook height 15m (50') and min operating range of 15m (50')

• heavy crane (Day 7 of installation / Day 2 of dismantling):

to pick 'crown' in one load 8,5t (19000lbs)

min hook height 25m above the centre of the fountain

e.g. mobile crane 120t (265000lbs)

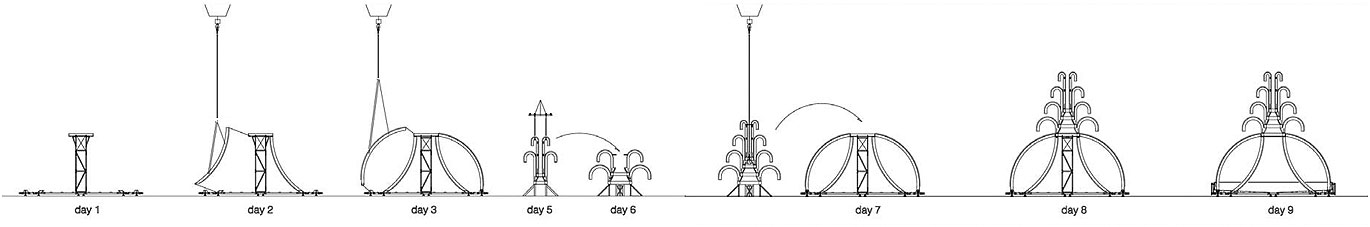

rough overview, in best conditions 12 working days with crew of six skilled workers + MHS project manager

day 1 – set-up site, installation of structural basis

day 2 – installation of inner beams

day 3 – installation of outer beams

day 4 – wiring

day 5 – installation of layer 1 and 2

day 6 – installation of layer 3 and 4

day 7 – wiring of crown / lifting of crown

day 8 – testing of electrical system

day 9 – covering of basis

day 10 – balustrade

day 11 – final testing, reports, programming control

day 12 – cleaning the site, acceptance and operation

rough overview, in best conditions 8 working days with crew of six skilled workers + MHS project manager

day 1 – set-up site, dismantling of balustrade and basis

day 2 – picking of crown dismantling of crown

day 3 – dismantling of outer beams

day 4 – dismantling of inner beams

day 5 – dismantling of basis

day 6 – final packing, clearing of the site

day 7 – control of whole equipment, packing sea containers

day 8 – packing sea containers, sealing

A define installation planning and cost estimation is possible after a first site meeting.

For the overall success of the exhibition on time of its opening please note:

• the whole equipment should arrive at a local storage at least 4 weeks before starting the actual installation, to being able to properly check on all elements (first of all the neon tubes) after the shipment and to have enough time to being able to rework possible damages.

• the overall period for the installation should not be less than three weeks, providing some reasonable extra time in case the electrical system / lighting control needs some time for clearance